PRODUCTION

At the

heart of the Czech Eagle mountains come to the world tables and chairs made by

already the fourth generation of the Kaplan family. We put our heart into care

for wood and the very production. The lines which follow are interwoven with smell

of forest, wood and love to craftsmanship. Welcome to our family workshop! You

are going to be acquainted with traditional and modern techniques, we always

use prior to delivery of our products to your home.

Cooperation

with top designers together with very long tradition of production enable us to

bring to the market the best solid wood tables and chairs.

1. Oak wood we process comes partly

from our own forests. From the first day we care for wood with love. When we

care for our small oak seedlings, we know we started to work on a future solid

wood oak table, which will be delivered to a customer around 2150.

1. Further wood for our wooden oak and beech tables we buy from forests near to us in the Eastern part of the Czech Republic directly from their owners. These forests are managed in sustainable way and their wood holds FSC certification. Directly in forests we assess and sort every single tree. At that moment we already know, which product will be produced from each of them.

Firstly, the wood for your new dining table is forwarded from forest to

a sawmill. There it will be cut into thicknesses and sizes, that we will use afterwards.

1. We give our utmost care to material

and its processing at all times. Therefore, we store sawn, up to 140 mm thick

and up to 120 cm wide, planks and boards in covered warehouses. Free air

circulation dries them out naturally. One or two years later we finalise drying

process using condensation drying kilns. The very prescribed process is

controlled by a computer. The heat we need for drying of wood comes from wood

chips, which are waste materials from production process. Thanks to a precision

work with raw material, your dining table and chairs will be entirely stable

and will not come unglued.

1. During production of chairs we

shorten individual planks, then we trace curves along a template on each of

them. At the same time, we pay attention to remove wood defects, which are

unacceptable for our products, while endeavouring to maximise the use of this

natural material.

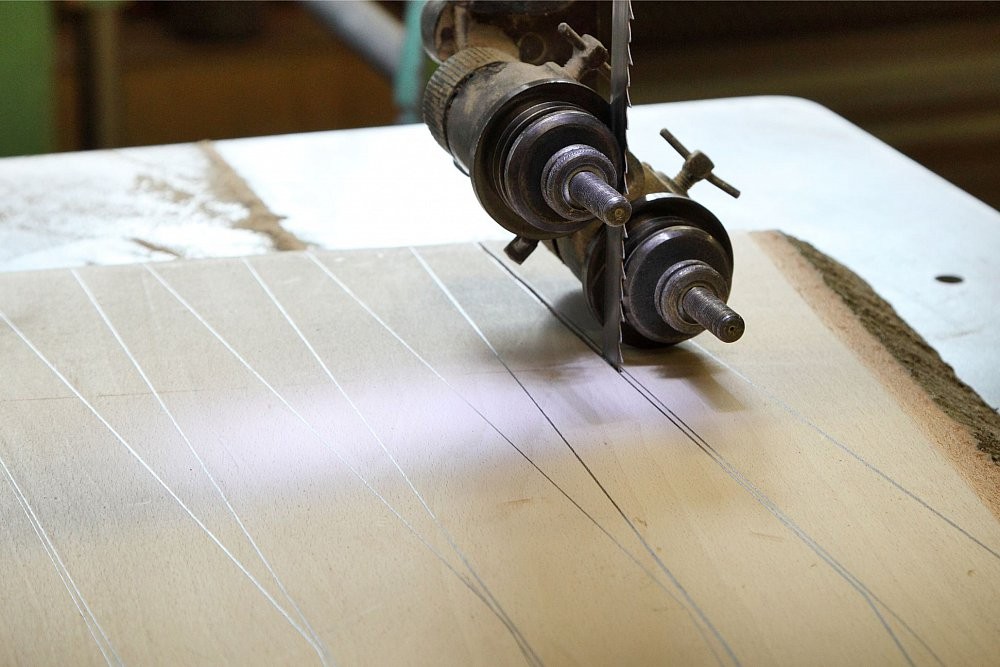

We get first rough shapes on wood

pieces, which come from cutting on a bandsaw. After this step it is easier for

you to discern, what will emerge from each piece of wood.

Simpler final shapes come out of a

copy milling machine. Precise and often complicated shapes designed by a

designer are milled using 7-axis machining centre. From that moment on, you

will be surely able to recognise your new wooden chair.

Individual pieces of chairs are

waiting before assembly in air-conditioned warehouse. Thousands of machined pieces

are stacked on dozens of pallets.

Our solid wood chairs of great

design are highly stable thanks to the glued mortise-and-tenon joints we use in

their whole construction. We glue all individual pieces carefully in precisely

prepared joints.

Your new dining table or chairs become

definitively reality once legs and aprons are joined together. We deliver all

our products in one single piece and they cannot be disassembled. Therefore,

they are very strong and will last you for a long time.

There is also another natural

product, which goes through our hands during production. Our second favourite

material is a quality natural hide. Upholstery for chairs, bar stools and

benches is made solely in hands of our experienced upholsterers. And the only

machine which is used during their production is a sewing machine. Every

upholstered chair made of this natural material is unique and slightly

different. That is the magic of our work and beauty and uniqueness of your

chairs.

Surface finish with matte coating

gives our extendable table excellent resistance. Natural oiled chairs and

dining table will bring into your dining room the smell of wood. We do specific

appearance and shade of wood stain for your furniture exactly to your order.

Finished, packed chairs and extendable table will be delivered to you by a special freight forwarding company.

The second life of a 100-year-old oak tree is about to start now.

We have never produced two identical chairs and we are convinced, that therein lies the beauty of work with natural materials.